Phoenix Manufacturing Facility Information

Phoenix Manufacturing and Design is a comprehensive CNC Mfg. facility

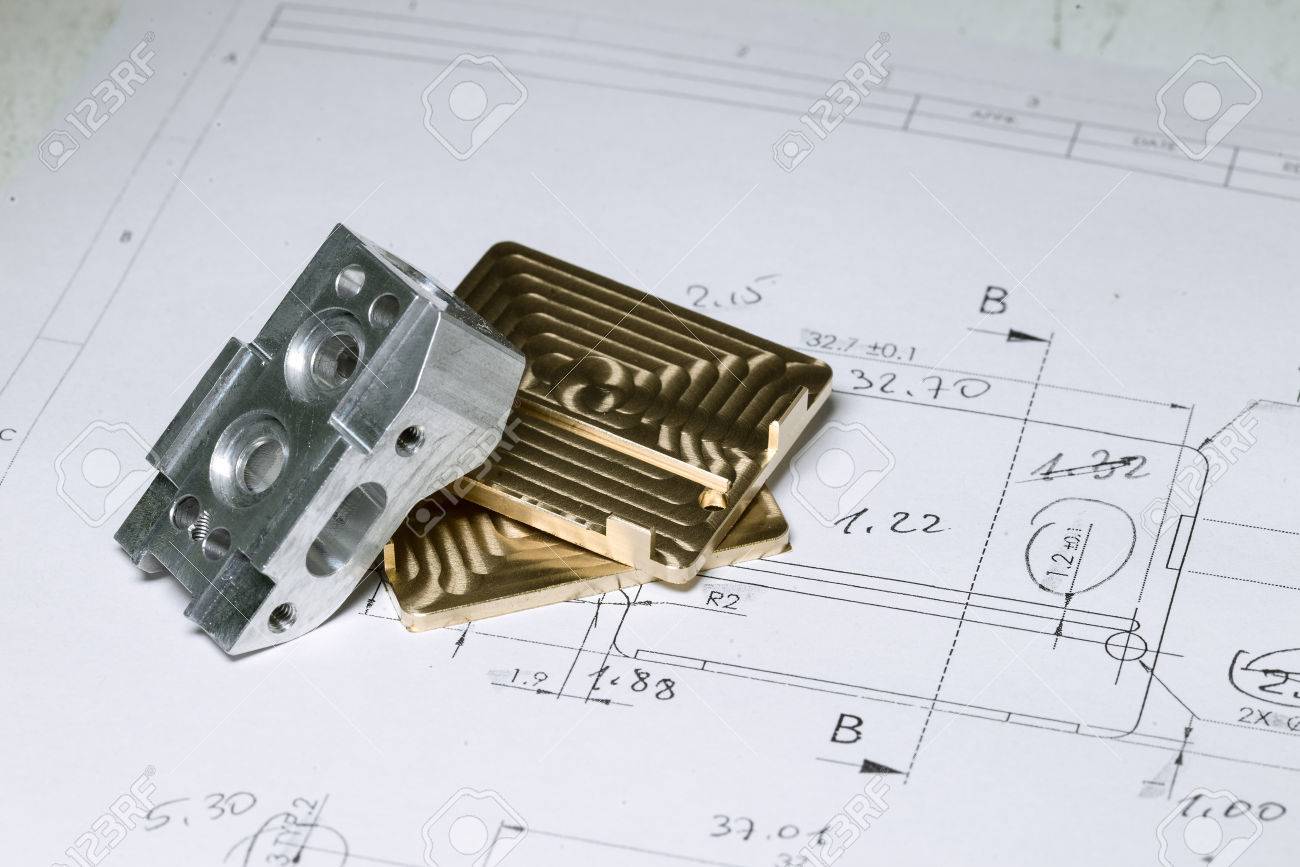

Phoenix Manufacturing and Design is a comprehensive facility offering precision machining, manufacturing, and design services. Equipped with state-of-the-art CNC (Computer Numerical Control) machining technology, we have the capability to cater to a wide range of requirements, from small-scale prototypes to intricate production parts.

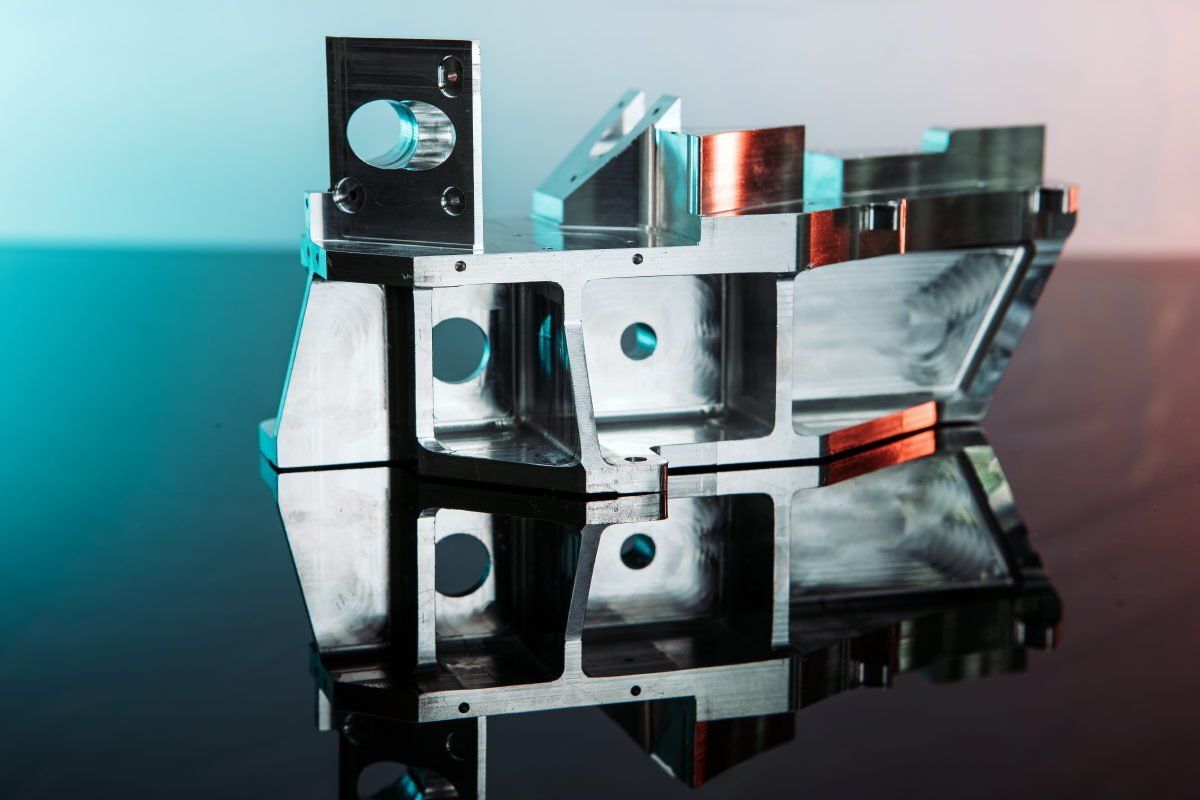

Our precision machining services are characterized by their high accuracy and consistency, ensuring that your components are manufactured with meticulous attention to detail. We employ advanced CNC machines, which are computer-controlled and capable of executing complex machining operations with precision and efficiency. This technology allows us to produce parts with tight tolerances, intricate geometries, and superior surface finishes.

In addition to our machining capabilities, we have an experienced team of designers who can assist you throughout the product development process. Whether you have a rough concept or a detailed design, our experts can collaborate with you to refine and optimize your ideas. By leveraging computer-aided design (CAD) software, we can create 3D models, perform simulations, and generate accurate manufacturing specifications.

Our manufacturing services encompass both short-run prototyping and large-scale production. We understand the importance of rapid turnaround times for prototypes, enabling you to evaluate and test your designs before moving into full-scale production. With our extensive experience in manufacturing, we can efficiently produce the required quantities of your components while maintaining the highest quality standards.

At Phoenix Manufacturing and Design, we are committed to delivering exceptional results to our clients. Our dedicated team of skilled machinists, engineers, and designers work collaboratively to meet your specific requirements and exceed your expectations. Whether you need precision machined parts for aerospace, automotive, medical, or any other industry, we have the expertise and resources to fulfill your needs.

Contact us today to discuss your project and discover how Phoenix Manufacturing and Design can be your trusted partner for precision machining, manufacturing, and design.

Phoenix Manufacturing & Design Equipment List

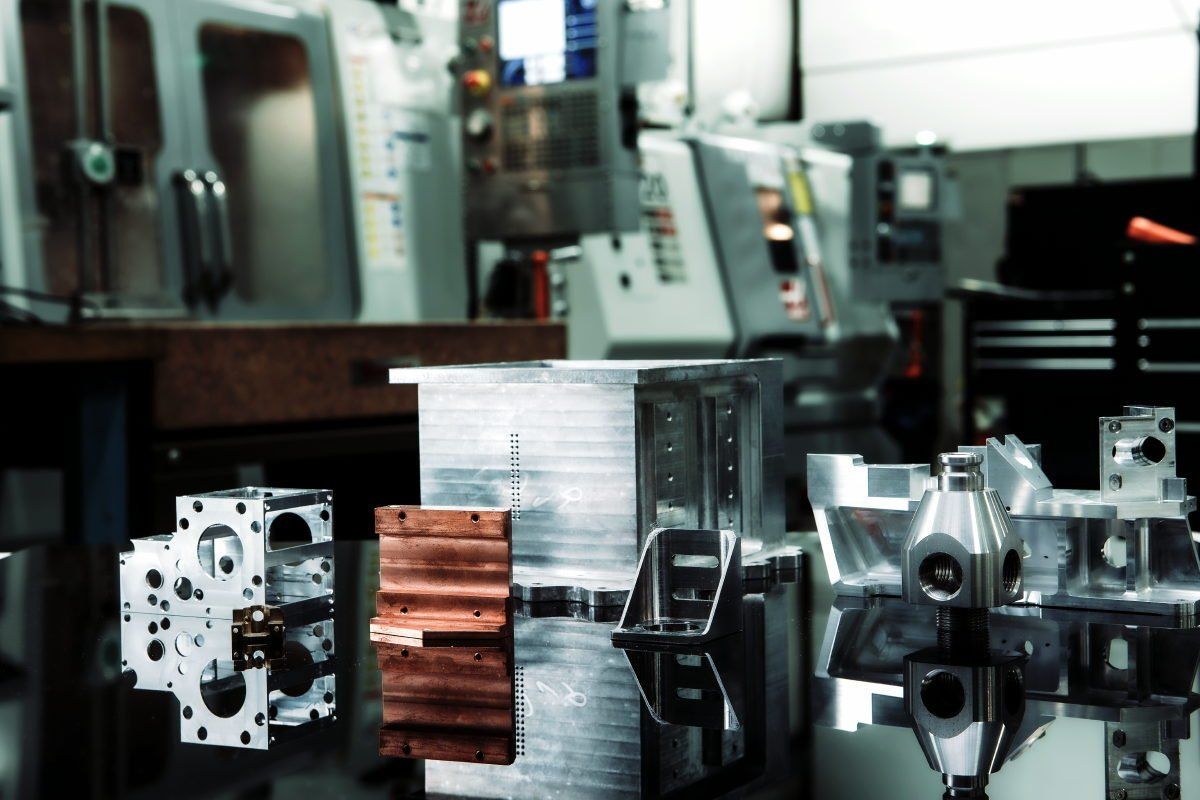

Phoenix Manufacturing & Design is equipped with state-of-the-art machinery to deliver precision manufacturing and design services. Our extensive equipment list includes:

- Kitamura MyCenter 4XiD Vertical Machining Centers: These machines feature 12k spindles and 20"x 40" travels, providing high-speed and accurate machining capabilities.

- Milltronics RW 20 3 axis cnc mill 8k spindle 20" x 30" travels usually used as a support mill for the EDM machines to manufacture tooling and fixturing.

- Mazak FH4800 Horizontal Machining Center: With a powerful 25k spindle and two 400mm pallets, this machine offers efficient and versatile horizontal machining operations.

- Fanuc Robodrill Vertical Machining Centers: Equipped with 10k spindles and 2 pallets, these machines ensure fast and reliable vertical machining processes.

- Haas VF-2s Vertical Machining Center: Featuring a 10k spindle, 4th Axis capability, and 16"x30" travel, these machines provide precision machining with added versatility.

- Mitsubishi FX-10 Wire EDM: Our two Mitsubishi wire EDM machines deliver precise cutting and shaping of workpieces.

- Ingersoll Gantry 500 Sinker EDM: This EDM machine offers efficient and accurate electrical discharge machining for intricate shapes and profiles.

- Doosan Puma GT2600 Turning Center: With advanced turning capabilities, this machine provides high-quality and precise turning operations.

- Haas SL-20T CNC Turning Center: Equipped with live tools and C Axis functionality, this CNC turning center enables complex and multi-axis machining.

- Slant 50 CNC Turning Center: This machine, along with a 4' bar feeder, offers efficient and reliable turning operations.

- HwaCheon Hi-Eco 10 CNC Turning Center: Delivering precise and high-speed turning operations, this machine ensures exceptional quality.

- Citizen L20ix 5 axis Swiss machine with 12 foot bar feeder

- Enshu JE60S Horizontal Machining Center: With a 12k spindle and two 400mm pallets, this machine offers efficient and versatile horizontal machining operations.

- Bridgeport 2-axis Prototrak knee mill: Offering versatile milling capabilities with accurate and repeatable results.

- Bridgeport knee mill with DRO: This knee mill, equipped with a digital readout, enhances precision and ease of use.

- Leblond Makino 15”x54” manual lathe with DRO: Providing manual turning operations with DRO for enhanced accuracy.

- Sharp 14”x40” manual lathe with DRO: This manual lathe offers reliable and precise turning operations.

- GMC 14”x40” manual lathe with DRO: Another manual lathe equipped with DRO for accurate and efficient turning processes.

- Harig Surface grinder: Ensuring smooth and precise surface grinding for various applications.

- Cincinnati tool grinder: Providing precise tool grinding for optimal tool performance.

- Sunnen MBB-1660 hone: This machine delivers precision honing for achieving tight tolerances and surface finishes.

- Tesa Micro-hite 3D Coordinate Measuring Machine: Ensuring accurate and reliable dimensional measurements for quality assurance.

- Brown & Sharpe Coordinate Measuring Machine: Offering precise and detailed measurements for quality control purposes.

- Deltronic optical comparator: This equipment facilitates accurate visual inspection and measurement of parts.

- Gage master Series Twenty optical comparator: Providing reliable optical inspection and measurement capabilities.

- Tesa Height gauges: Ensuring accurate height measurements for precise machining operations.

- Starrett surface plates: Offering a stable and flat surface for precise measurements and setup.

- Miscellaneous inspection tools: We have a range of specialized tools to support accurate inspection and quality control.

- Heat treat ovens: Two heat treat ovens are available for precise heat treatment processes.

- Miller Tig and Mig welders: These welding machines enable precise and reliable welding operations.

- Misc. Shop support equipment

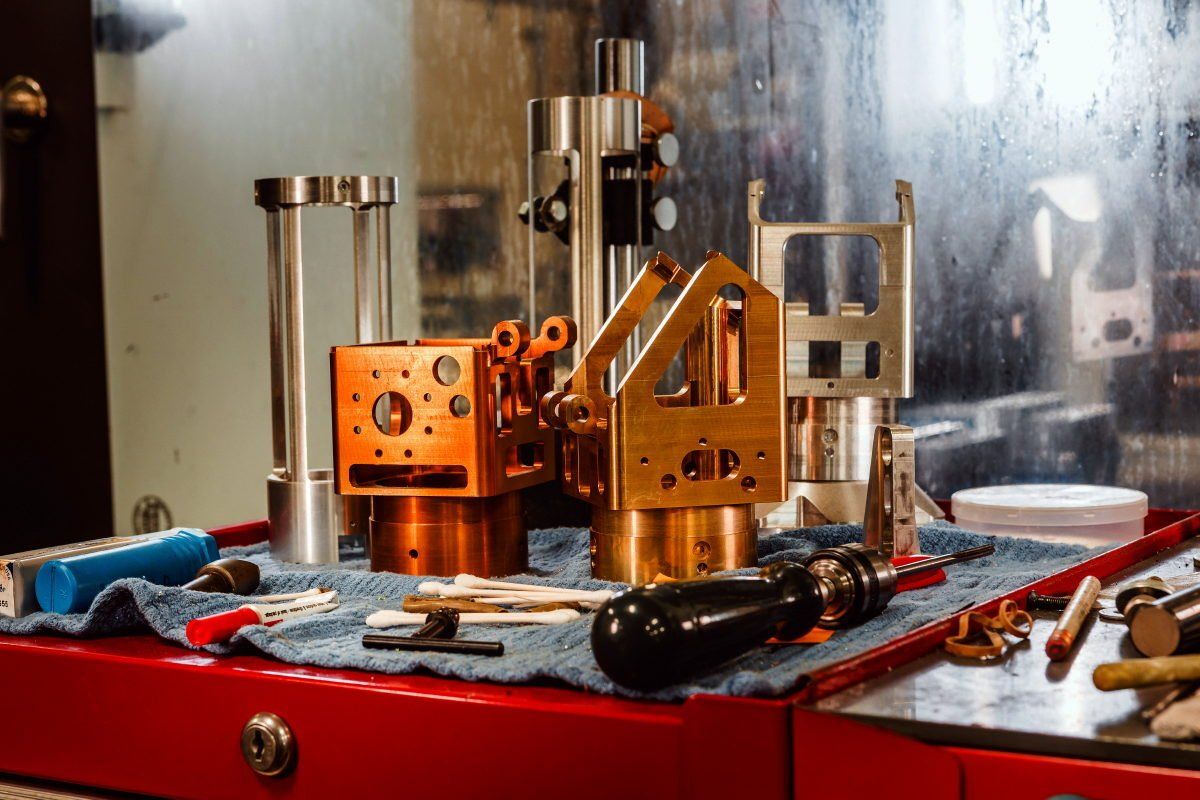

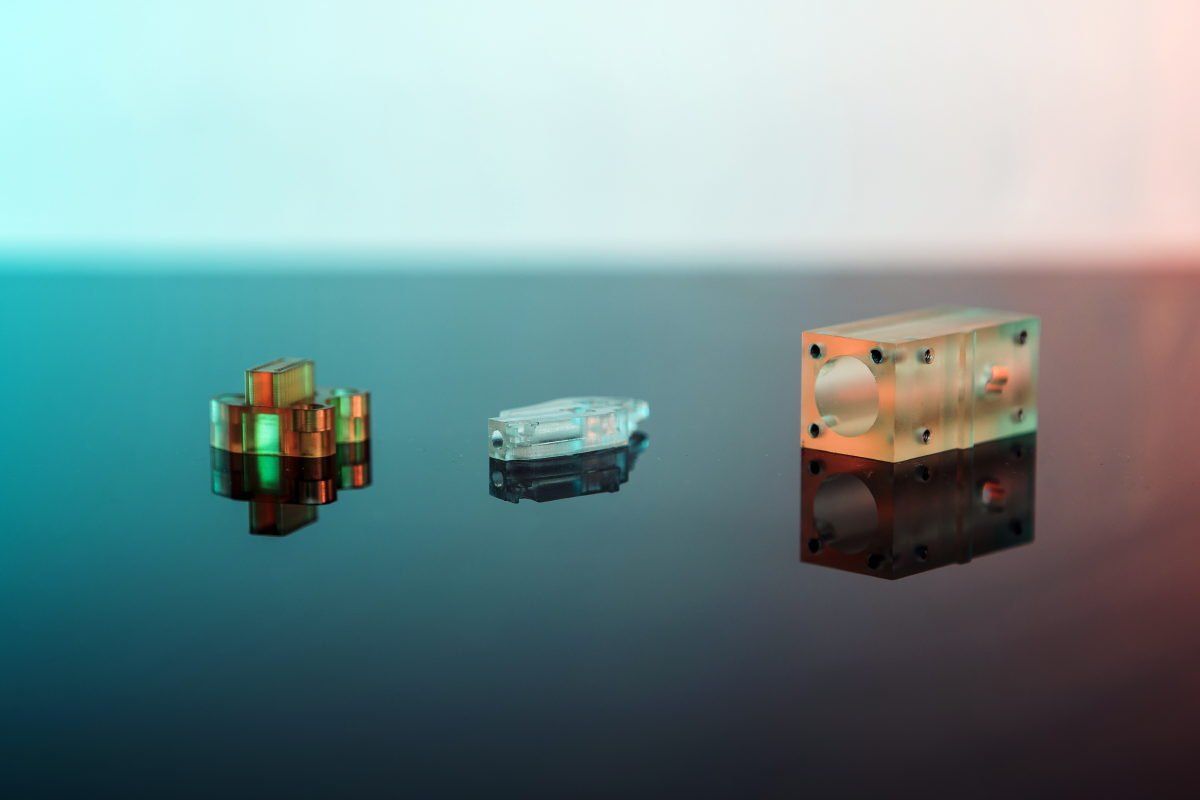

Phoenix Mfg. & Design Equipment & Shop Photo Gallery

Quick turn, Precision Machining of domestic and exotic material

Full product Life Cycle Support

- Concept

- Design

- Engineering

- Development

- Prototyping

- Production

Industries

- Aerospace

- Automotive

- Automation

- Medical

- Hi-Tech

- Firearms

- Energy

Materials

- Exotic Aerospace alloys

- Ferrous Metals

- Non Ferrous Metals

- Plastics